On Friday Cary and I met Mark out at the site in the afternoon to go over the connections for the utilities, as well as some other items. Bruce, my neighbor and the head of the Water Association, also came over to see if he could help solve the big mystery: where the #@$&% IS the water line? You see, we have a faucet in the shop, but we've never been able to locate a shut-off or meter or any other clue as to how the pipe was laid that conncets that faucet to the main water association line. The main water association line follows the driveway, which goes along the north edge of our property, then turns south and runs along the west edge. Since the shop is located in the NW corner of the property, the connection line could come either from the north or from the west... or for extra fun, it might zig zag or run diagonally. There are NO records, and although I've hunted around in all the bushes many times over the last few years, we've never found ANYTHING to indicate where the water line was buried.

Locating the water line recently became a bit more urgent, and not just because we need to connect into it for the house supply. The real problem was that we planned to ditch through the area by the shop to collect the phone, cable, and propane supply lines, and it'd be a real bummer to find the water line by breaking it with a backhoe. Especially considering that without a shut-off valve, we'd have to shut down water to the whole neighborhood while we fixed it.

Well, we all walked around on Friday, and still had no idea where the line was. Mark and Cary even dug a hole where we found an old stake in the ground which might have marked

something - nothing. So I volunteered myself and Cary to dig around by hand on Saturday and try to find it.

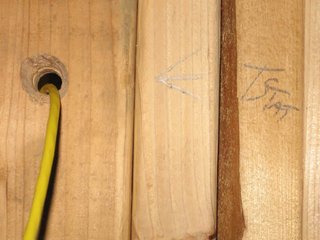

We started by digging about 20 feet away from the west wall of the shop, where the phone and electric lines were marked by the locator. Our reasoning was that if somebody was going to hook up multiple ulilities, they'd use as few ditches as possible. Also, the faucet inside the shop is right next to the phone jack. We found the phone line almost immediately, about 1' down. We kept going but the clay was hard and wet, looked like it had never been disturbed, and to top it off our hole started to fill up with water. Then the handle of the post hole digger broke. Gaah.

We widened our trench and continued digging, bailing the water out, but it was getting pretty miserable. We felt certain we'd gone down 24" (the standard depth for electric lines) but we'd found nothing. I started to doubt that the electrical line was where it had been marked. Not knowing where the water line is bad, but not knowing where the electrical line is worse.

So, we changed tactics. We moved over to side of the shop, right outside from where the phone, faucet, and fuse box are on the inside. The reason we didn't start digging there in the first place is that the shop is build on a 1-2 foot thick pad of pit run, and we'd thought that it would be more difficult to dig through all the rocks than it would be in the clay. However, we were pleasantly surprised to find that a combination of pitchfork and shovel made relatively quick work of the pit run - and we found not only the electrical line but also the water line! Hooray! Now we just had to establish that the water ran straight west, and didn't turn and head north 5 or 10 feet from the building. Back to that first, nasty, water filled hole. Cary said "I guess this is what makes us homeowners, and not renters, huh?"

Well, down about another 6 inches, and yessiree, there was the water and the electric line.

The water was coming in fast, flowing right down the pipe. I had a bad feeling about that, but mostly I was just happy we'd found it...

And sure enough, Mark called this morning from the site, where they had expanded the utility ditch and found the crappy shut-off that somebody jerry-rigged with a regular faucet valve and then buried. Apparently it's leaking pretty badly, due to the fact that it's not the sort of valve that you are supposed to use as a shut-off or bury in the ground at all, let alone for 15+ years. We have to put in a new valve and a meter anyway, so it's not going to cause any additional expense, I'm just glad we found it now and not sometime next year!